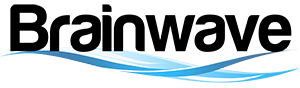

SNAP BRACKET

Availability – Single, Contractor 6 Pack, Contractor 12 Pack

Type – 1 and 2-Gang Low Voltage Bracket

AVAILABLE PRODUCTS & SKU’S

- 630-SNAPBRKT1 – 1 Gang Snap Bracket (1)

- 630-SNAPBRKT1CP – 1 Gang Snap Bracket – Contractor Pack (6)

- 630-SNAPBRKT2 – 2 Gang Snap Bracket (1)

DESCRIPTION

GET IT DONE IN A SNAP WITH SNAP BRACKET. JUST TRACE, CUT, AND SNAP!

The 1 and 2 Gang Low-Voltage Old Work Snap Bracket is a low-Voltage mounting bracket requiring minimal installation effort. The snap bracket features a built-in template to make wall prep easy. Then simply extends into place, providing an easy solution for hiding low-Voltage cables in the wall.

The non-metal frame can be used for virtually any low-voltage wire application, including telephone, cable or audio and home theatre connections.

BENEFITS AND FEATURES

- Easy faceplate installation

- Compatible with most low-voltage, old work applications

- Bracket ships with the spacer in place for installation in 1/2 inch or 5/8 inch dry-wall

- Spacer is removable to accommodate 5/8 inch drywall by releasing snap-fits

- Backside spikes temporarily secure bracket while perimeter line is drawn

- Tool-less and removable bracket installation

- Rachet threats facilitate device installation – push screw in and only one screw rotation to tighten

- UL Listed – E361961

SPECIFICATIONS

ONE GANG SNAP BRACKET

SKU: 048243909513

- Weight: 0.049 lb.

- Dimensions: 3.75 in x 2.5 in x 0.8 in

- Material: PC + ABS (Fire Rated)

- Dyrwall Thickness: 1/2 in – 5/8 in

TWO GANG SNAP BRACKET

SKU: 048243909513

- Weight: 0.074 lb.

- Dimensions: 3.75 in x 4.3 in x 0.8 in

- Material: PC + ABS (Fire Rated)

- Dyrwall Thickness: 1/2 in – 5/8 in

WARRANTY

N/A

HOW TO BUY

Electrical wholesalers, telecomm installers, cable manufacturers & any related professionals may buy the Snap Bracket in palette quantities. Please click to enquire for more details or email rpardo@brainwavecorporation.com for delivery, shipping costs and master packs.

INSTALLATION

Printer friendly instructions here

FOLD TABS FORWARD, PUSH INTO WALL AND MAKE LEVEL

CLOSE BRACKET, TRACE AROUND ONTO DRYWALL, USING DRYWALL SAW CUT OUT BRACKET OUTLINE

FLIP TABS UP ACCORDING TO DRYWALL, SNAP BRACKET UPWARDS AND ATTACH PLATE